9%

Weniger Maschinenstillstand

23%

Gesparte Cloud-Kosten

13%

Reduzierter Ausschuss

17%

Geringerer Energieverbrauch

Führende Hersteller setzen auf Connectware

Metallverarbeitung | Automotive | Maschinen- und Werkzeugbau | Landmaschinenbau

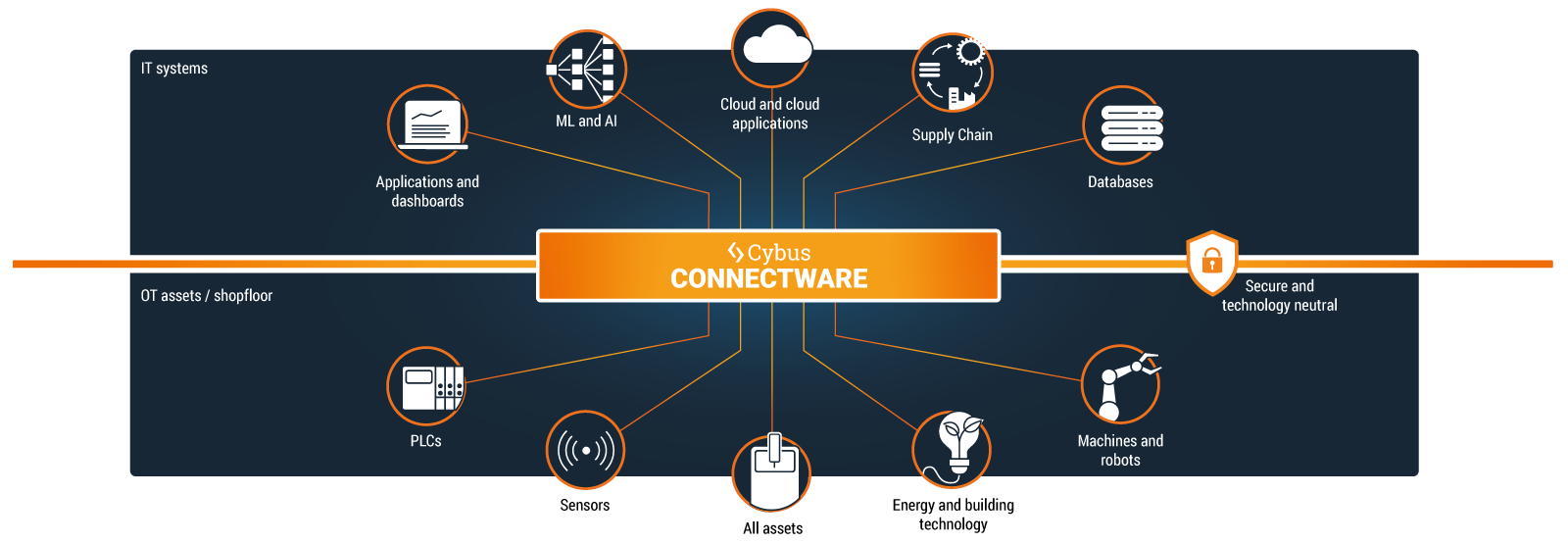

Eine unternehmensweite, industrielle Dateninfrastruktur

Connectware bildet eine einheitliche Datengrundlage für Ihre gesamte Digitalisierung

Cybus Connectware ist ein zentralisierter Factory Data Hub, der industrielle Daten sammelt, verarbeitet und verteilt. Er unterstützt komplexe und skalierende Konfigurationen über mehrere Fabrikstandorte hinweg und ist speziell für den produktionskritischen Betrieb ausgelegt.

Entfalten Sie das Potential Ihrer Daten mit Performance, Geschwindigkeit und Skalierbarkeit

Beschleunigen Sie Ihre Digitalisierungsinitiativen mit einer standardisierten Dateninfrastruktur und nahtloser IT/OT-Integration

Skalierender Datenfluss

Eine hochskalierbare Konfiguration ermöglicht effiziente Rollouts. Mit automatischen Skalierungen gelingt eine standardisierte Konnektivität für alle Produktionsstandorte.

Echtzeit-Einblicke

Direkter Zugriff auf alle Echtzeitdaten aus IT- und OT-Quellen. So kann Ihr Team Anwendungsfälle schnell, unabhängig und kosteneffizient implementieren.

Industrielle Konnektivität

Die standardisierte Dateninfrastruktur stellt ganzheitliche und hochverfügbare Konnektivität bereit. Integrieren Sie alle Systeme und Anwendungen nahtlos mit Connectware.

Vorteile für Sie und Ihr gesamtes Unternehmen

Innovation und Exzellenz in der Umsetzung und im laufenden Betrieb

OT

Unabhängig von der IT arbeiten

Integrieren Sie Produktionsanlagen schnell und mühelos, um Dateneinblicke in Echtzeit zu erhalten.

IT

Umfassende Data Governance

Echtzeit-Zugang zu industriellen Daten für die Personen, die sie benötigen. Sicher, einheitlich und steuerbar.

Fachabteilungen

Realisieren Sie Ihre Use Cases in wenigen Wochen

Fördern Sie das Geschäft durch die rasche Durchführung von Initiativen, die Produktionsdaten benötigen.

Maßgeschneidert für jedes Ihrer digitalen Projekte

Realisieren Sie Ihren Use Case mit wertvollen Echtzeit-Daten

Die wichtigsten Features von Connectware

Sichere Datenintegration für hochkomplexe Systeme und Setups

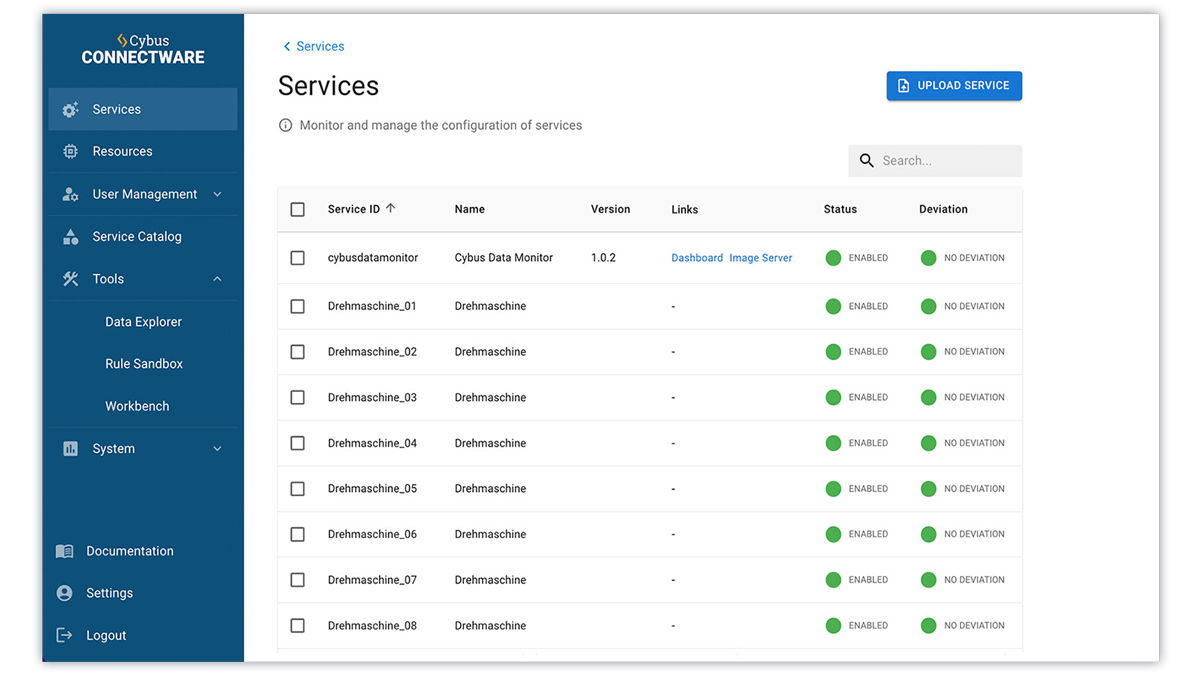

Die Connectware Benutzeroberfläche auf einen Blick

Intuitive Konfigurationen und angeleitete Datenintegration für komplexe Produktionslandschaften

Service-Übersicht

Informationen über alle laufenden Services übersichtlich zusammengefasst, einschließlich Status und Abweichungen.

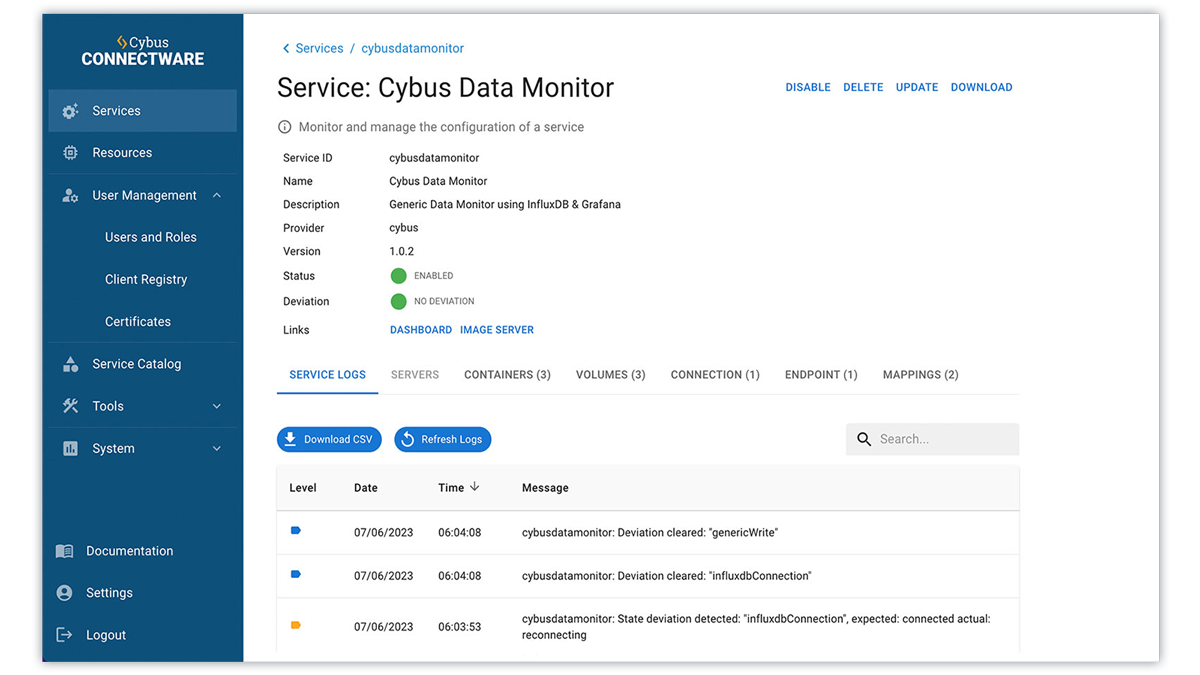

Service-Details

Informationen über alle relevanten Details eines Services und den vom Service verwendeten Ressourcen, einschließlich der einzelnen Verbindungen und Daten-Endpunkte.

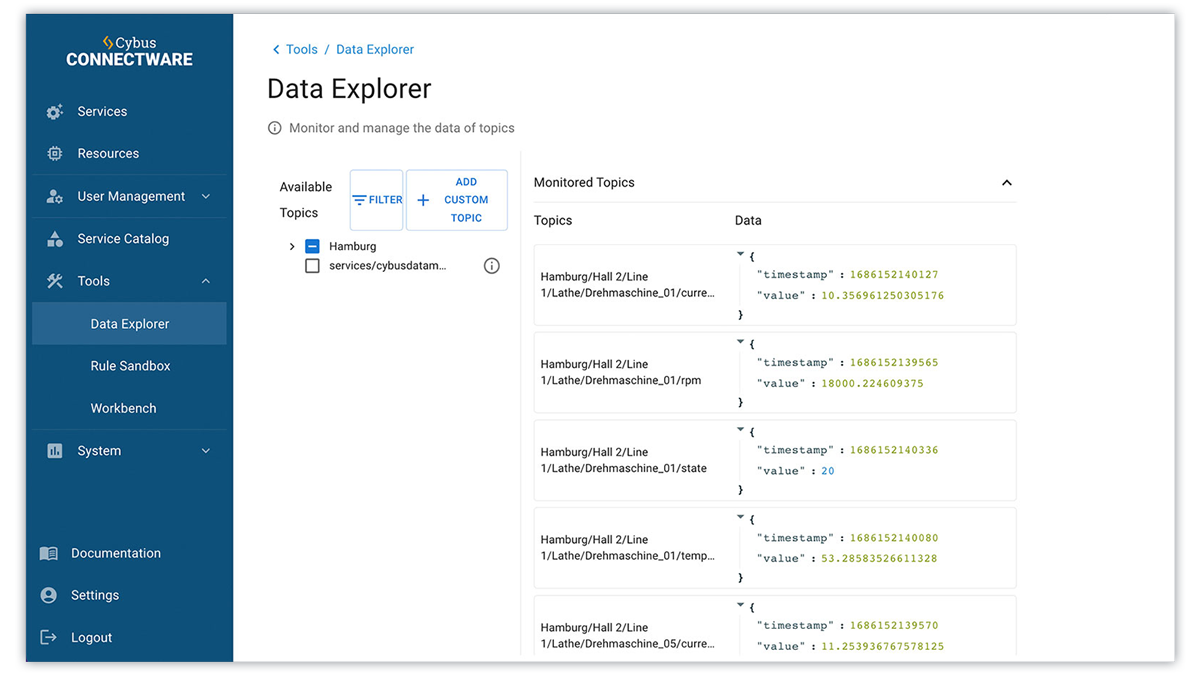

Data Explorer

Durch die Visualisierung Ihrer Dateninfrastruktur können Sie alle industriellen Daten Live überblicken und erkunden.

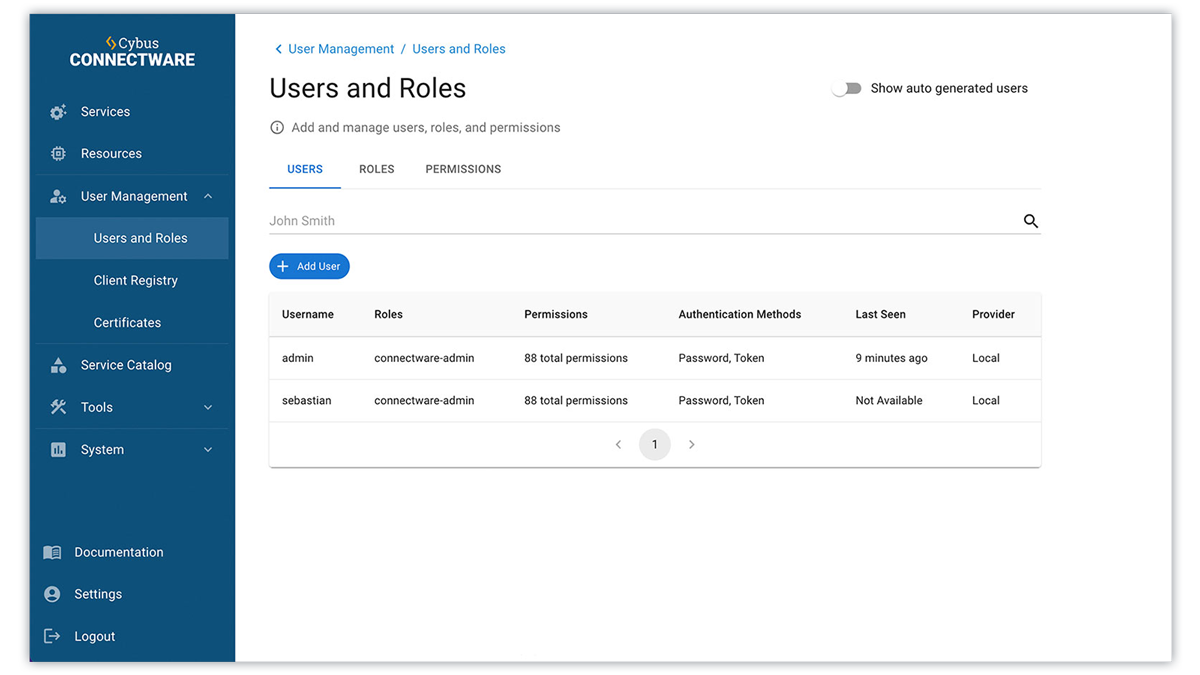

Benutzer und Rollen

Organisieren Sie den Zugang und die Benutzerrechte für alle Connectware-Nutzer, um die Kontrolle und die Sicherheit über den Datenzugriff zu gewährleisten.

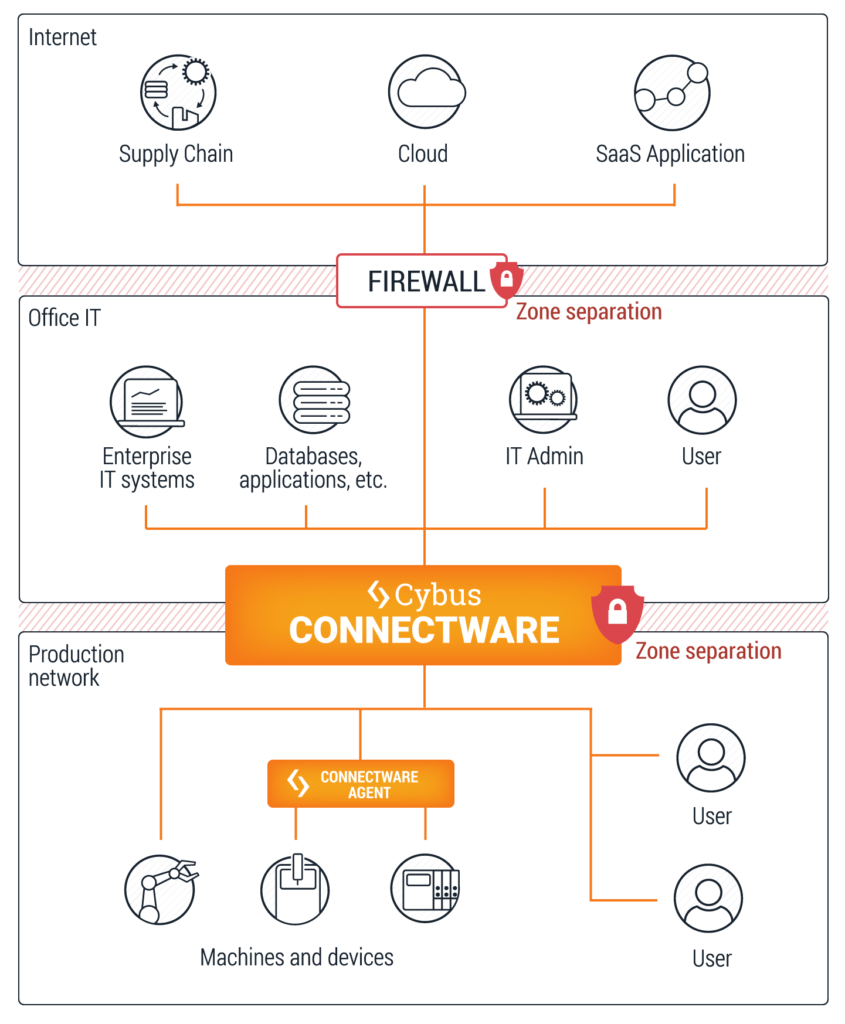

Industrial IoT Architektur

Integrieren Sie Ihre Netzwerk- und Systemlandschaft nahtlos mit Connectware

Eingesetzt in Ihrem Fabriknetzwerk

Stellen Sie Connectware einfach am Edge Ihres Fabriknetzwerks bereit – ohne Ausfallzeiten in Ihrer Produktionsumgebung.

Sicheres Gateway zwischen Produktionen und IT

Durch den Aufbau einer technologieneutralen Schicht entkoppelt Connectware die Datenerfassung von der Datennutzung.