-

Use Cases

Industrien

Getting started

-

Insights & Wissen

Für User

Support

SUCCESS STORY DEUTSCHE NICKEL

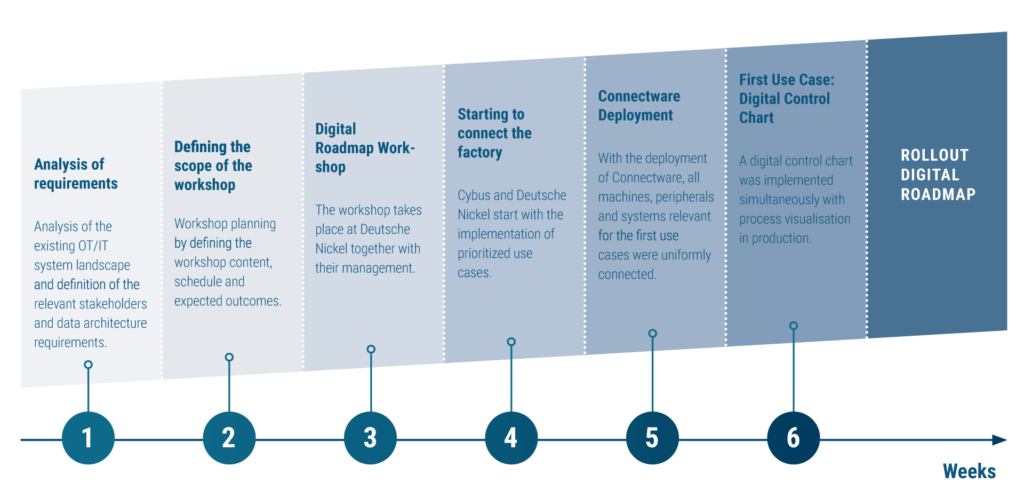

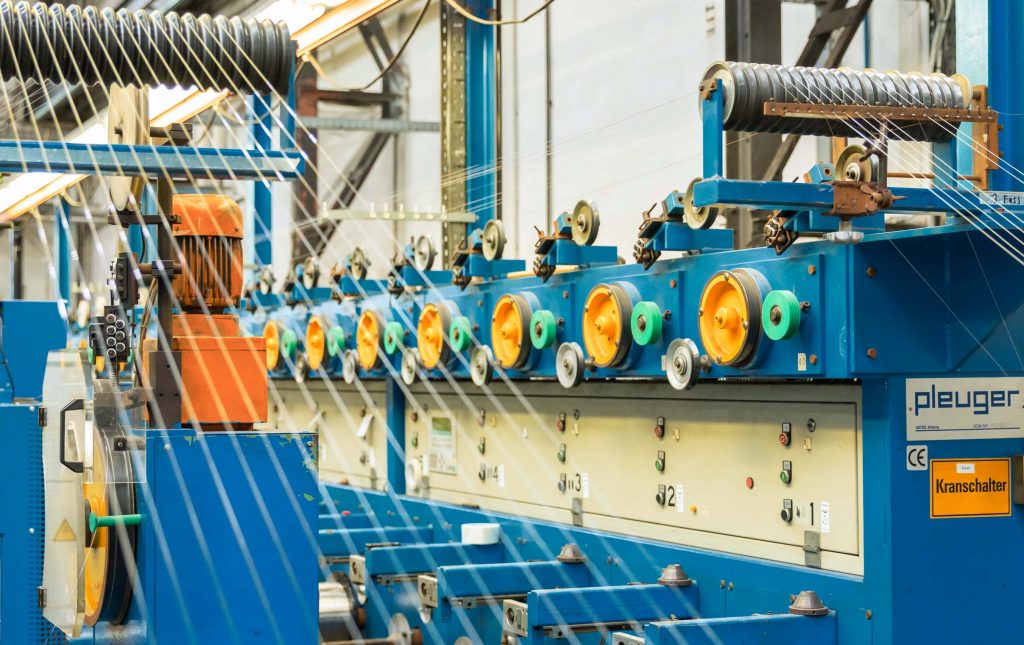

Die Deutsche Nickel GmbH ist einer der größten Hersteller von Draht und Stangen aus Nickel und Nickel-Legierungen. Mit digitalen Transformationsprojekten und einer handlungsorientierten Digitalisierungs-Roadmap begegnet Deutsche Nickel erfolgreich den Marktherausforderungen wie steigender Nachfrage, hohen Qualitätsanforderungen und Produktionseffizienz. Zusammen mit Cybus realisiert Deutsche Nickel in nur sechs Wochen erste IIoT Use Cases und bringt Smart Manufacturing und Prozesstransparenz in Ihr Werk.

Pragmatisch und in nur eineinhalb Tagen erarbeitete Deutsche Nickel im Digital Roadmap Workshop mit Cybus eine Digitalisierungs-Roadmap mit ergebnisorientierten und individuell zugeschnittenen Use Cases. Wo früher schwer zu erfüllende Anforderungen die Vorhaben verlangsamt haben, ermöglicht die industrielle Dateninfrastruktur der Connectware alle geplanten Schritte mit den modernsten Technologien.

Jede Investition in Digitalisierungsmaßnahmen muss letztlich zur Steigerung der Wirtschaftlichkeit beitragen. Deshalb identifiziert Cybus mit seinen Kunden stets konkrete Use Cases.

Mit einer klaren Priorisierung fokussierte Deutsche Nickel sich auf folgende Use Cases:

Mit dem Connectware Deployment hat die Deutsche Nickel den Grundstein für die erfolgreiche Transformation zur Smart Factory gelegt. Connectware stellt den unternehmensinternen Teams sämtliche Produktions- und Maschinendaten zur Verfügung. Damit können alle geplanten Projekte dank der universellen Dateninfrastruktur eigenständig realisiert werden.

Sie sehen gerade einen Platzhalterinhalt von HubSpot. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenCONSULTING WORKSHOPS

Nach dem Workshop haben Sie eine digitale Produktionsstrategie, eine digitale Roadmap und einen wirkungsvollen Handlungsplan für Ihre digitale Transformation. Der konkrete und abteilungsübergreifende Umsetzungsplan ermöglicht Ihnen die direkte Realisierung erster Use Cases und führt zu unmittelbaren Kosteneinsparungen.

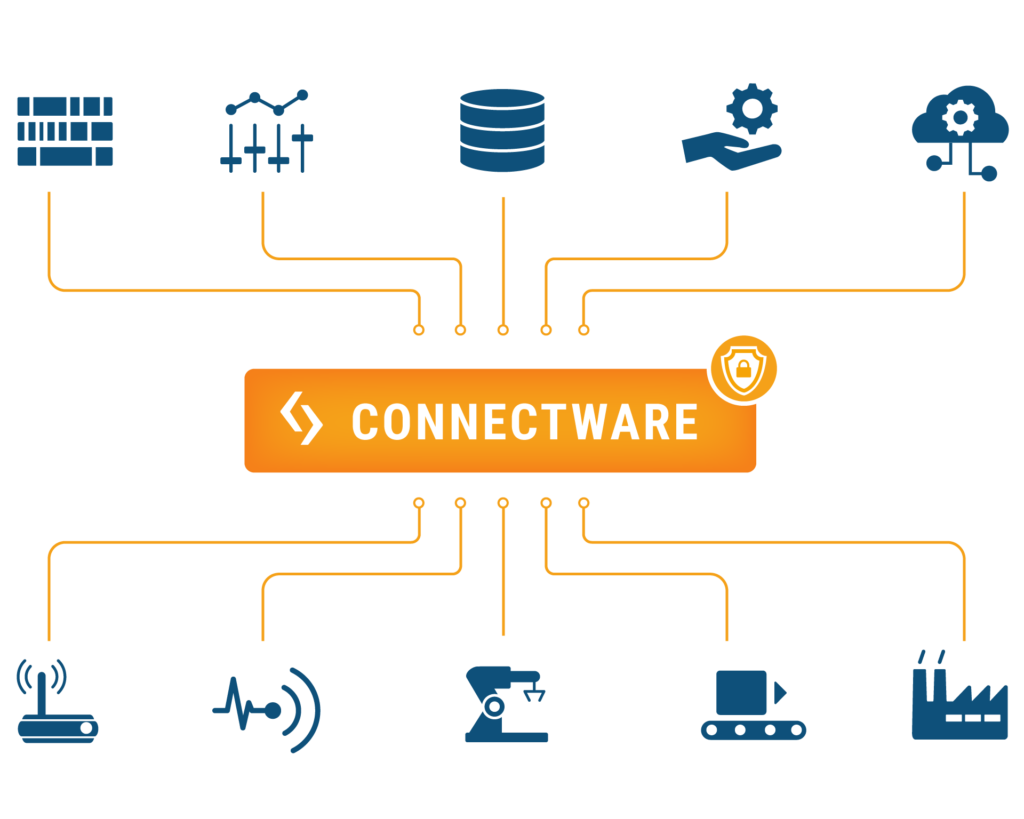

CYBUS CONNECTWARE

Mit dem führenden Factory Data Hub Connectware realisieren Sie Ihre ersten Schritte der Digitalisierung bis hin zur Smart Factory Transformation. Neben voller Shopfloor-Konnektivität für den Produktivbetrieb schafft Connectware zusätzlich eine skalierbare Datenarchitektur für Ihre digitalen

Projekte – ohne Grenzen.

Eine Plattform für alle IIoT Projekte, unabhängig von

Schnittstellen und Herstellern.

CYBUS CONNECTWARE

Cybus Connectware sammelt nicht nur Daten, sondern standardisiert sie in eine einheitliche Sprache, verarbeitet sie entsprechend Ihren Anforderungen vor und verteilt sie an jedes System, jede Anwendung und jede Cloud. So können Sie Ihre Maschinendaten sofort im Dashboard visualisieren und erweiterte Analysen und maschinelles Lernen durchführen.

Ihre Ausgangslage und Anforderungen sind komplex und einzigartig. Darum möchten wir Sie im ersten Schritt besser verstehen.

sales manager

Ob Metallverarbeitung, Automobilindustrie oder Werkzeugbau – führende Industrieunternehmen setzen auf den Factory Data Hub

Sie möchten herausfinden, was Sie mit Cybus Connectware in Ihrer Fabrik erreichen können? Gerne tauschen wir uns mit Ihnen über Ihre Anforderungen und Vorhaben aus und führen Sie in einer live Demo durch den Factory Data Hub Connectware.

Sie müssen den Inhalt von reCAPTCHA laden, um das Formular abzuschicken. Bitte beachten Sie, dass dabei Daten mit Drittanbietern ausgetauscht werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Facebook. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Instagram. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von X. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen