-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

SUCCESS STORY DEUTSCHE NICKEL

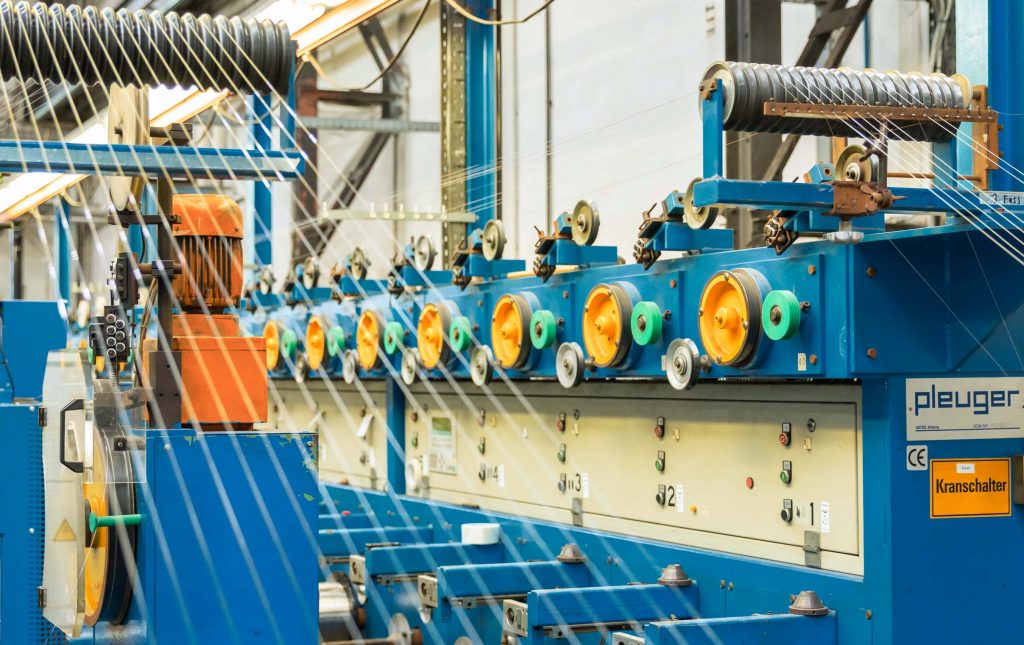

Deutsche Nickel GmbH is one of the largest manufacturers of nickel and nickel alloy wire and rod. With digital transformation projects and an action-oriented digitalization roadmap, Deutsche Nickel successfully meets challenges such as increasing demand, high quality requirements and production efficiency. Together with Cybus, Deutsche Nickel implements the first IIoT use case in just six weeks and brings smart manufacturing and process transparency to its shop floor.

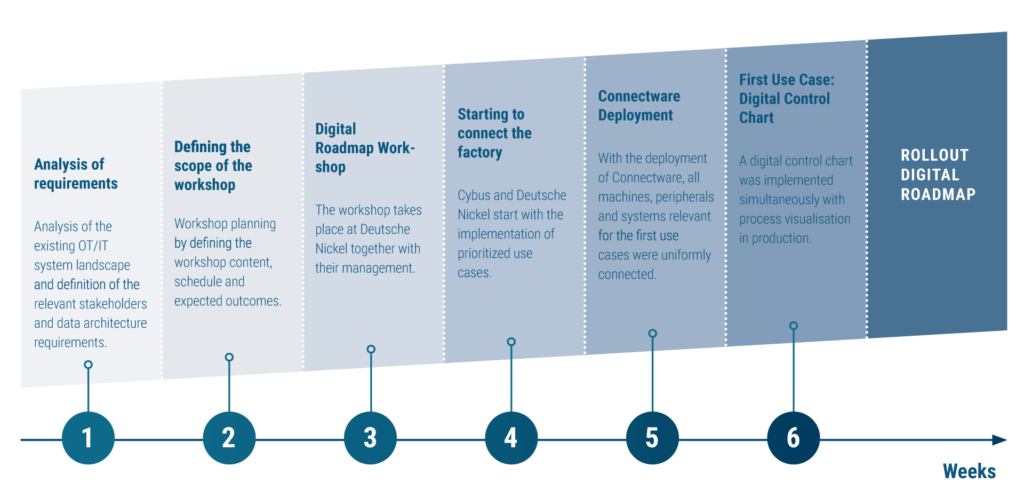

In just one and a half days, Deutsche Nickel has developed a digitalization roadmap with result-oriented and individually tailored use cases in the Digital Roadmap Workshop with Cybus. Where previously challenging requirements slowed down their digitization projects, Connectware’s industrial data infrastructure now makes it possible to implement all planned steps with the latest technology.

Every investment in digitization projects must ultimately contribute to increasing profitability. That is why Cybus always identifies concrete use cases with its customers.

With a clear prioritization, Deutsche Nickel focused on the following use cases:

With the deployment of Connectware, Deutsche Nickel has laid the foundation for their successful transformation to a smart factory. Internal teams now have constant access to all relevant production and machine data. As a result, all planned projects can be implemented independently thanks to the universal data infrastructure.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCONSULTING WORKSHOPS

After the workshop, you will have a digital production strategy, a digital roadmap and an effective action plan for your digital transformation. A concrete implementation plan enables direct realization of use cases and leads to immediate cost savings through targeted measures.

CYBUS CONNECTWARE

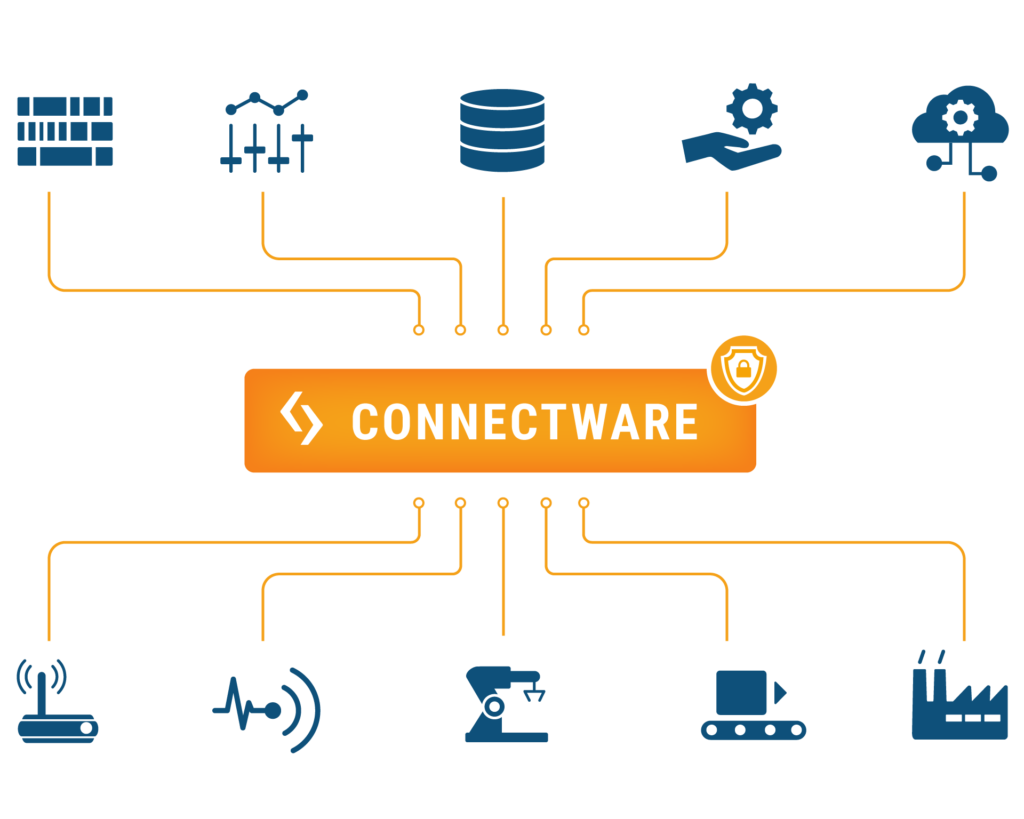

With the leading factory data hub Connectware you realize your first steps of digitalization up to full Smart Factory transformation. In addition to full shop floor connectivity, Connectware also creates a scalable data infrastructure for your digital projects – without limits.

CYBUS CONNECTWARE

Cybus Connectware not only collects data, but also standardizes it to a common language, preprocesses it according to your requirements and distributes it to any system, application or cloud. As a result, you can instantly display your data on the dashboards, perform advanced analytics or machine learning.

Your initial situation and requirements are complex and unique. That’s why we want to understand you better in the first step.

Sales manager

Whether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub

Would you like to find out what you can achieve with Cybus Connectware in your factory? We would be happy to discuss your requirements and plans with you and guide you through the Factory Data Hub Connectware in a live demo.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information