-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

CONNECTIVITY PORTFOLIO | What is Beckhoff ADS?

Automation Device Specification (ADS) is a device- and fieldbus-independent interface to devices manufactured by Beckhoff Automation. It functions as a transport layer within the TwinCAT system. This protocol was designed to enable data exchange between different software modules (e.g. the NC and the PLC).

Implementing this protocol with the Cybus Connectware enables seamless communication to ADS devices in the shopfloor. It also provides the user with the ability to create endpoints for reading and writing as well as to subscribe for changes on the data provided by them.

With Cybus Connectware, Data from Beckhoff PLCs can be made available on MQTT in JSON Format or OPC UA, normalized or enriched with meta data and forwarded to IT systems like databases, SCADA systems, dashboards, data lakes or IoT Platforms like Azure or AWS.

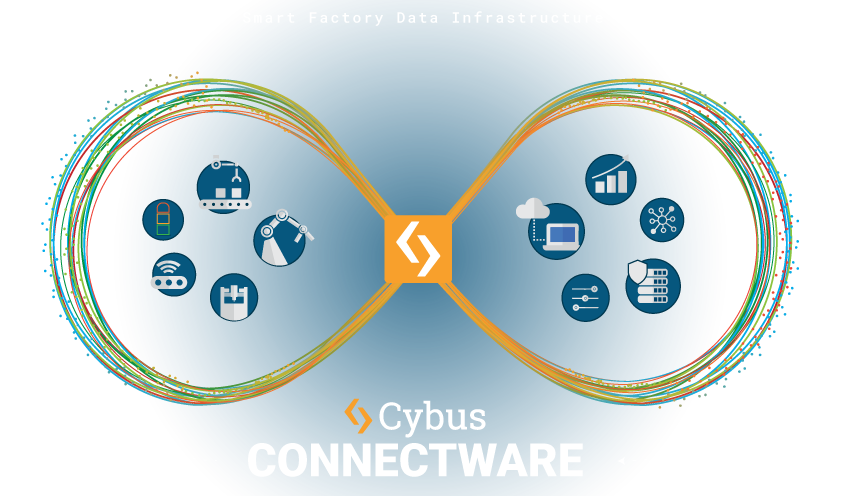

CYBUS CONNECTWARE

The leading Factory Data Hub Connectware is suitable for the first steps of digitization up to the Smart Factory transformation. In addition to universal shopfloor connectivity, Connectware creates a scalable data infrastructure for digital projects without limits. One single platform for all IIoT projects, independent of applications and vendors.

Would you like to discover what you can achieve with Cybus

Connectware in your factory? We are happy to discuss how you will realize your digital projects efficiently and quickly.

Sales manager

You are currently viewing a placeholder content from Zoho Bookings. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information ‘You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information