-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

PREDICTIVE MAINTENANCE I USE CASE

Predictive maintenance is one of the key drivers of Industry 4.0. Based on historical production data, assumptions are made for future machine or plant status, thus optimizing maintenance and servicing. Properly implemented, predictive maintenance increases the effective production time of your plants by significantly shortening maintenance times. Through optimal plant control, you save avoidable costs for spare parts and increase workplace safety.

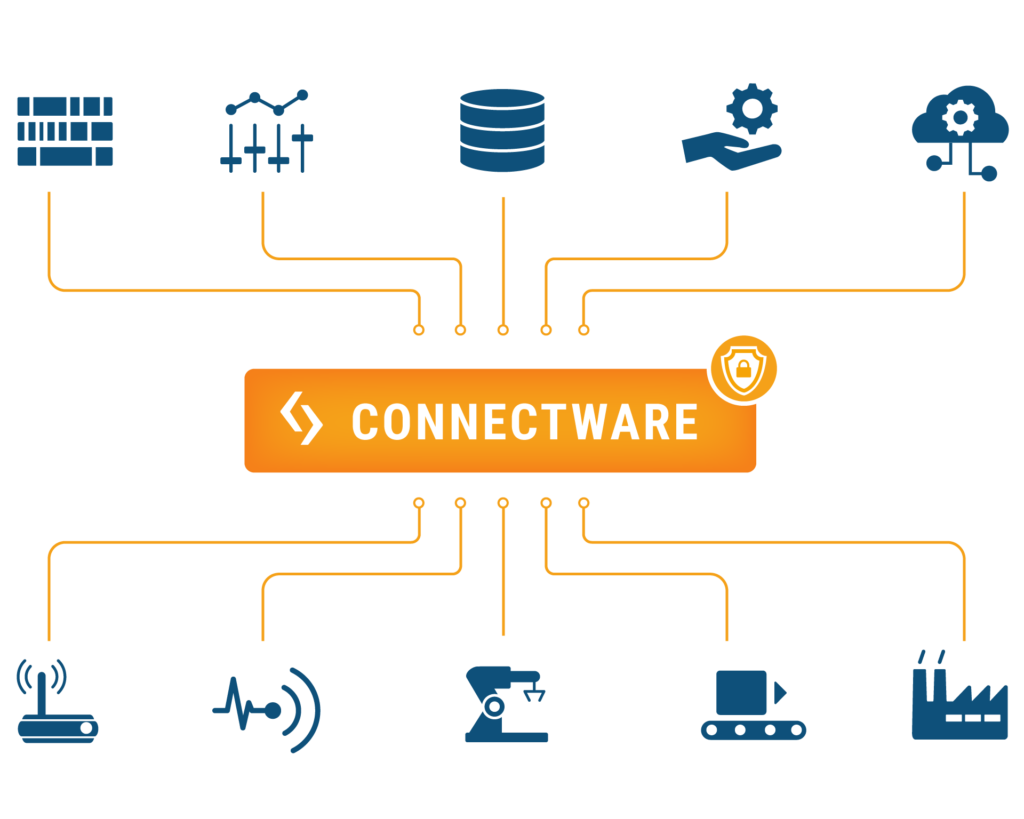

LIVE data acquisition

With Cybus Connectware, production data is collected, standardized and pre-processed in real-time and on-premises: You define individual thresholds, notification criteria and rules for data pre-processing. Through the strict security gate and access rights management, you decide which data is transmitted to authorized target applications, systems and clouds.

avoiding downtimes

For the implementation phase, it is essential to generate the first measurable added value in a short time. At the same time, production operations must not be disrupted. This requires non-invasive, local data acquisition and integrated solutions. With pre-qualified services and partner applications, Cybus Connectware enables reliable and compatible solutions for your production.

leveraging optimization potential

When you monitor and leverage your machine data, continuous improvement succeeds: Cybus’ universal data infrastructure provides you with all the data you need to optimize production so that you can:

Would you like to find out what you can achieve with Cybus Connectware in your factory? We would be happy to discuss your requirements and plans with you and guide you through the Factory Data Hub Connectware in a live demo.

Sales manager

you might also be interested in

Condition monitoring provides individual machine parameters in real time so that malfunctions can be detected and instantly corrected. Gain insightful production metrics, reduce downtime and optimize your production processes through reliable real-time data with Cybus.

cybus connectware

The leading Factory Data Hub Connectware is suitable for the first steps of digitalization up to Smart Factory Transformation. In addition to full shop floor connectivity, Connectware creates a scalable data infrastructure for digital projects without boundaries. One platform for all IIoT projects, independent of interfaces and manufacturers.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information