-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

ENERGY-EFFICIENT PRODUCTION

Production downtimes hinder fast and valuable process optimisation. With CI/CD, updates, optimisations and adjustments to production processes can be carried out during ongoing operations – quickly, cost-effectively and without risk.

ENERGY-EFFICIENT PRODUCTION

Solve the challenging steps towards Energy Management. Connectware enables you to centralize and converge real-time energy data throughout all your factories. Track how much energy each factory, machine, component and production step consumes.

control of all production processes

Integrating an MES with Cybus Connectware does not require any intervention in live production. The universal data layer from Cybus provides your live data pre-processed and specially prepared for your MES.

shop floor transparency

Continuous improvement can only succeed if you track and know your machine conditions. With the help of a user-friendly visualization in an intuitive dashboard, your employees will be able to optimize production and detect errors or malfunctions on their own.

forecast with real-time insights

Based on your own production data, you make reliable assumptions about machine conditions and possible failures. In this way, you optimize your entire maintenance and reduce cost-driving downtimes.

universal data flow

Cybus Connectware’s technically neutral data infrastructure seamlessly connects the production with IT. Machine and plant data from fully connected production is transferred securely and in real-time to the cloud or any other system. This strategic decision enables the implementation of many digital use cases.

acquisition OF OEE KEY metrics

With the acquisition of OEE metrics, you create the best prerequisite to increase plant productivity and to continuously optimize your production. With Cybus Connectware you gain all relevant key metrics based on your machine and plant data in the shortest possible time.

the whole production at sight

In order to trace and document every aspect of the manufacturing of your products, seamless traceability is indispensable. Cybus Connectware allows you to collect your process data locally and in real time. The open architecture allows you to use any system or application for traceability.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

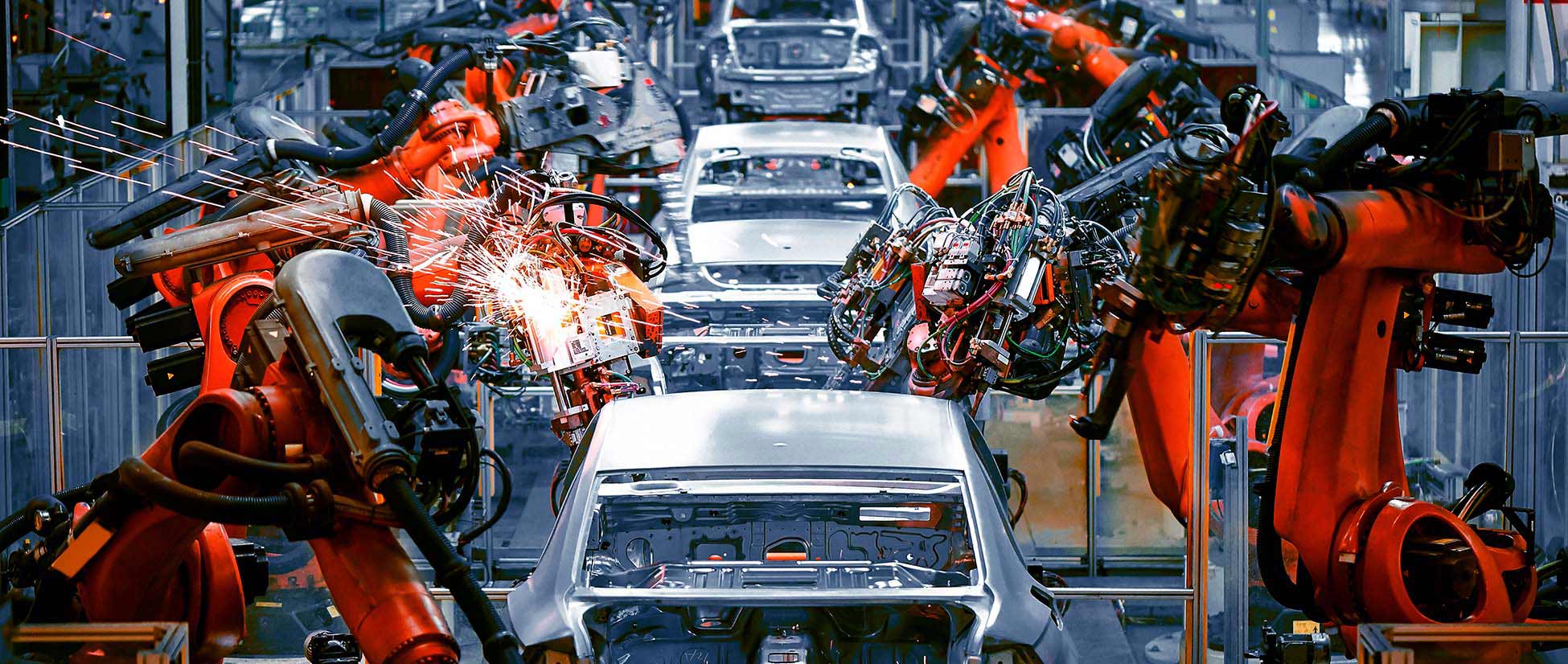

More InformationWhether metal processing, automotive or toolmaking – leading manufacturers rely on the Factory Data Hub

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information