-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

9%

23%

13%

17%

IT takes control, operations accelerates onboarding, business validates outcomes faster and leadership scales with confidence.

Centralized governance, fewer one-offs, secure multi-site operations.

Onboard machines quicker, monitor in real time, reduce vendor dependence.

Quicker results in quality, energy and OEE – with data you can trust.

Clear path from pilots to enterprise programs with visible ROI.

Legacy setups trap use cases at one site. Without a Unified Namespace (UNS) to standardize and govern your data, every rollout becomes a new project.

The longer you wait for a unified layer, the more every use case costs to scale.

With semantics, templates and governance by design, Cybus Connectware delivers scalable rollouts, flexible deployments and secure ops across every site.

Kubernetes‑native clustering plus MQTT buffering, retry and agent‑based prioritization keeps global operations resilient at scale.

Deploy on‑prem, in the cloud or hybrid – containerized and vendor‑agnostic to fit any IT strategy and existing security policies.

Git‑controlled YAML templates and central policies standardize rollouts – plants keep site‑level autonomy for fast local changes.

Reusable templates, automation & CI/CD let small teams roll out new factories in weeks – reducing setup effort and project risk.

Connectware filters, normalizes and enriches data in real time – across OPC UA, S7, MQTT and REST – for MES, dashboards and AI.

Encrypted pipelines, MFA, LDAP integration and network segmentation – with role‑based access to secure global rollouts by default.

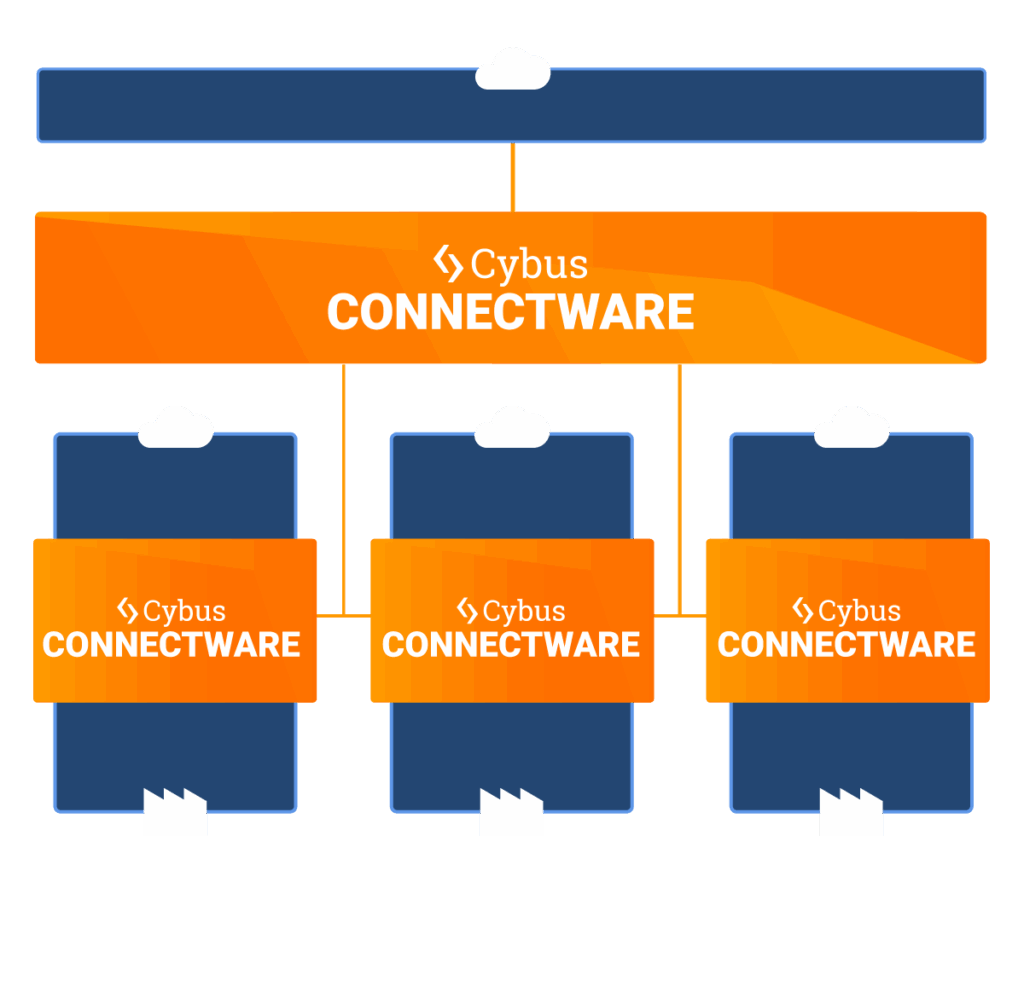

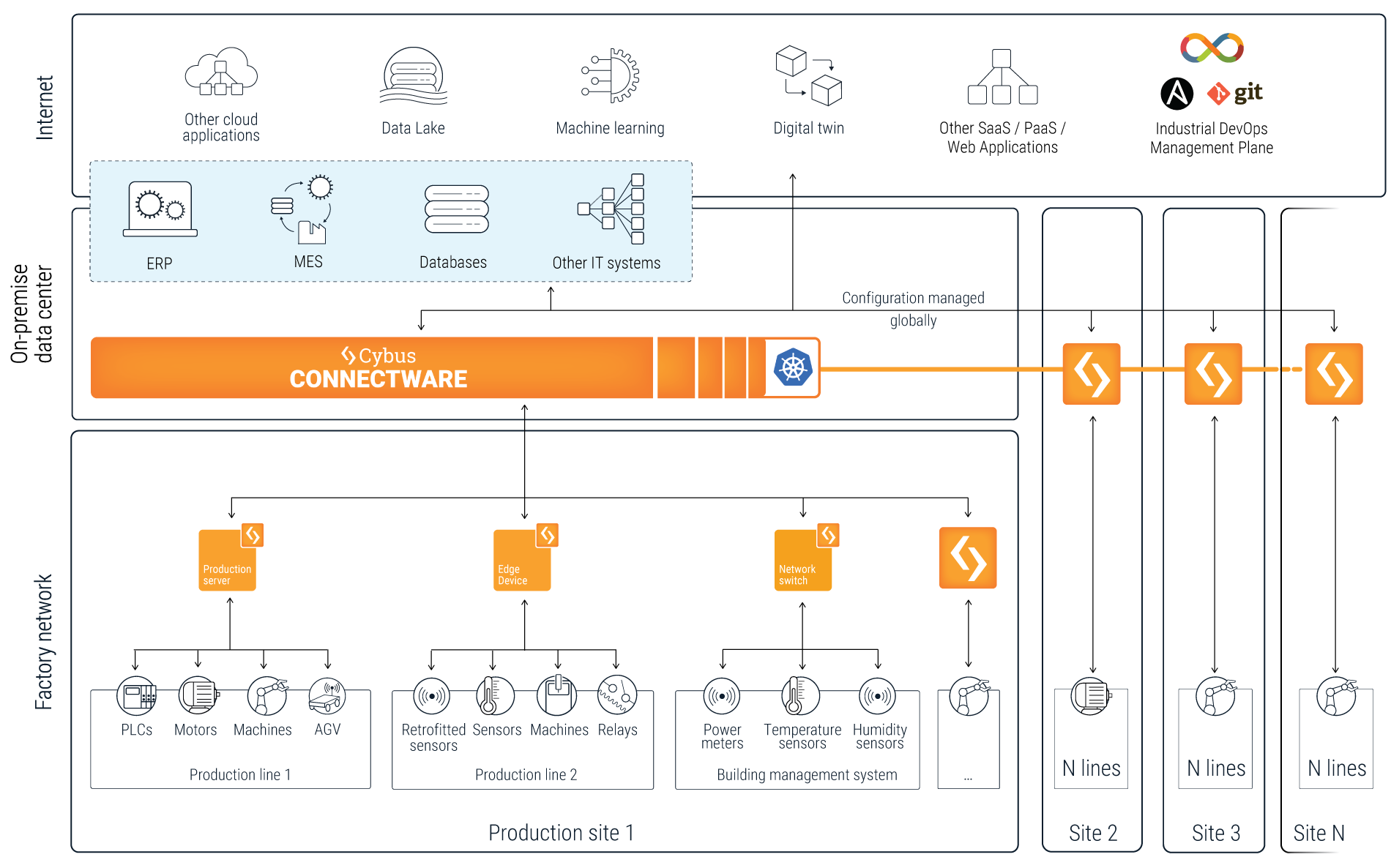

This architecture shows how Cybus Connectware operates as the Industrial Data Management between OT and IT – and how it fits into your existing factory set-up.

It standardizes data from PLCs and machines to MES, ERP, data lakes and AI, with configuration managed centrally via Git and rolled out on Kubernetes.

Start small, scale fast. From one machine to multiple sites, Cybus Connectware keeps the structure, logic and governance consistent at every step.

From code to connectivity, from YAML to real-time. Watch the 30-second demo of how UNS (ISA-95) works inside Cybus Connectware.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information