-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

News | 14.08.2025

If you’re responsible for keeping a factory running, you know the drill – when the line goes down, every minute matters. But what happens when the cause isn’t clear? IT is still waiting for updates, the service provider can’t be reached and no one remembers exactly what was changed last. It’s in those moments you realize just how little service structure exists for manufacturing – or Operational Technology (OT) – and how much is lost in terms of productivity costs.

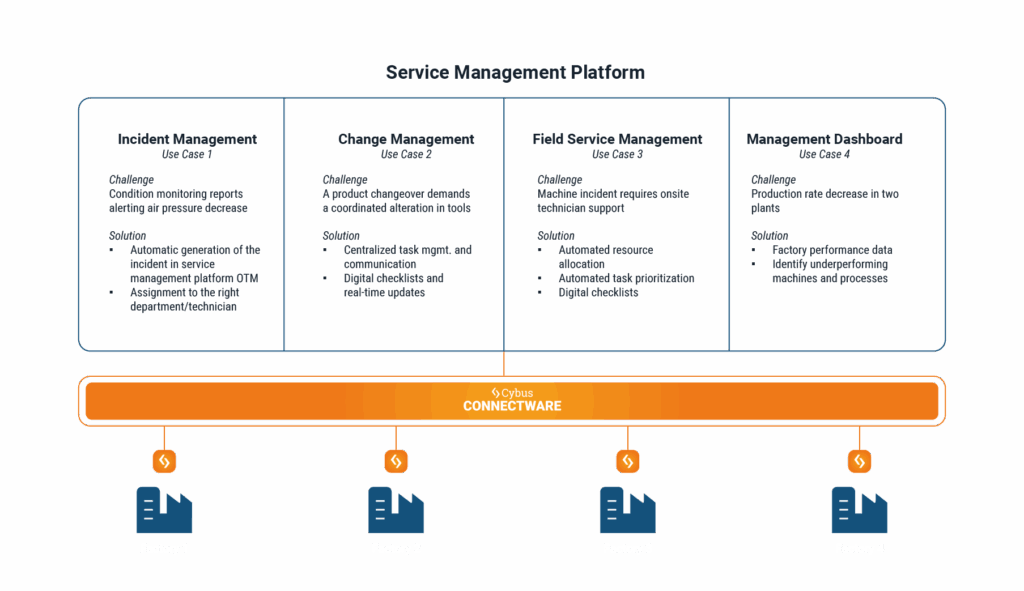

That’s exactly where Operational Technology Service Management (OTSM) steps in. It streamlines every technical process around machines, systems and vendors, making operations noticeably more efficient. Not as a top-down IT directive, but as a hands-on tool built for the realities of the shop floor.

Expert article by

Danny Rybakowski

Head of Partner Management, Cybus

In most factories, disruption handling follows a set playbook – Jidoka, Andon, you name it – and roles are clear. But take a step back and the cracks appear. Was that machine just updated? Have we seen this issue before? Is the part on the shelf – or weeks away? Without a complete, connected view, these answers stay scattered.

What’s missing? A central service management system that logs every incident, maintenance task, change and security issueand automatically kicks off the next steps. Whether it’s checking spare parts or alerting the right team, it keeps productivity moving instead of stalling.

IT already runs this way: every incident tracked, every change documented, every system in one database. It works. So why doesn’t it for OT?

OTSM gives production teams the structure they need to run equipment with confidence. This isn’t about turning manufacturing into IT. It’s about building processes that are clear, efficient and rock-solid when the pressure’s on.

Here’s what changes:

In short: You get visibility, speed and control. And the results show up fast.

A three-site manufacturer was losing time to unexplained downtime. Root cause hunts dragged on. Logs were missing. Data was patchy. Then they rolled out OTSM – with Cybus Connectware as the central data hub and ServiceNow as the platform – and things changed fast:

The result: In under six months, uptime jumped 11%. Zero new hardware. Just better processes.

For OTSM to work in the real world, you need three things: clean data, process expertise and an integration solution that ties it all together.

The best part? Your existing OT infrastructure stays exactly as it is. OTSM layers on top to enhance and improve what you already have.

Productivity doesn’t just come from new machines or automation. It thrives when processes are clear, information is at your fingertips and teams work in sync. OTSM is the key –especially for OT teams aiming higher than simply “keeping things running.”

If you suspect your production isn’t hitting its full potential, it’s time to take a closer look at OTSM. And if you want to see exactly what that could look like for your operation – Cybus can show you.

We’ll bring service management right where it’s needed most: onto your shop floor.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information