-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

News | 07.04.2025

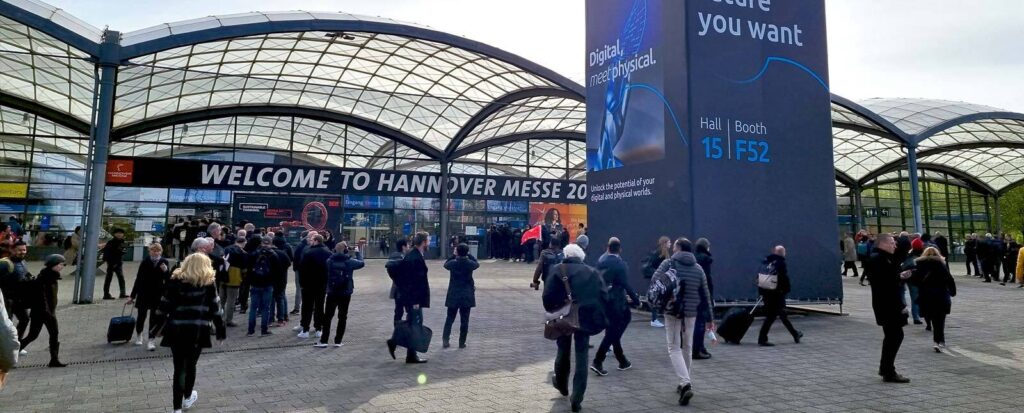

From March 31 to April 4, 2025, Cybus showcased innovative solutions for industrial connectivity and data integration at Hannover Messe 2025. Focusing on Unified Namespace (UNS) and Industrial DevOps, the company demonstrated how modern OT-IT integration can make production processes more efficient and scalable.

A highlight of the exhibition was the latest version of the Factory Data Hub Connectware, featured alongside live demonstrations from battery cell production, household goods manufacturing and collaborations with industry partners such as Capgemini, Microsoft Azure and Siemens. Visitors experienced firsthand how leading manufacturers achieve multiple production optimizations daily and connect up to 10 sites per year – all without disrupting ongoing operations.

Throughout the five-day event, attendees had the chance to explore Connectware across various booths (ServiceNow, Capgemini, Dell and Cybus), witnessing automated robots, SAP integration and much more in action. These dynamic showcases illustrated how a centralized data infrastructure provides a single source of truth for IT systems and serves as a universal foundation for a wide range of use cases.

Hannover Messe 2025 attracted approximately 127,000 visitors from 150 countries and more than 4,000 exhibitors across the mechanical engineering, electrical, digital and energy industries. Key topics included the digitalization of complex production processes, the use of hydrogen to power factories and software solutions aimed at capturing and reducing the carbon footprint.

By rolling out a standardized data infrastructure blueprint across six sites per year, Miele demonstrates how scalable and efficient brownfield digitization can become a key success factor on a global scale.

Real-time production data is seamlessly integrated into maintenance and ticketing systems, enabling faster response times and improving production quality.

MES and MES integration from a single source: The seamless compatibility of Siemens OpCenter and Connectware makes MES integration effortless.

In the hands-on Masterclass “From Hype to Reality: A DevOps Way to a Sustainable, Flexible Production,” our Industry Solution Architect, Luca Stephan, demonstrated how companies can successfully transition from isolated pilot projects to a scalable, digital production environment. The critical success factor: Industrial DevOps.

The core message of the sold-out event was clear: Digital transformation isn’t driven by technology alone – it requires the seamless integration of people, processes and technology. By establishing clear roles and responsibilities alongside a flexible data infrastructure, organizations can create a central digital platform — the Factory Data Hub — providing the foundation for long-term scalability and rapid adaptability.

The session tackled real-world challenges like heterogeneous machine systems, friction between IT and OT teams and overcoming “pilot purgatory” – the trap where successful pilots never transition into full-scale operations. Working collaboratively as a Center of Excellence, participants explored how Industrial DevOps principles deliver real solutions: standardized processes, clear governance and a culture of continuous improvement that breaks down silos, scales projects and keeps organizations agile for the future.

The overwhelming demand – all 40 seats filled quickly – underscores just how vital this topic is for today’s manufacturing companies.

Our Gin & Tonic Networking Event at Hannover Messe 2025 has become a must-attend highlight of the industrial fair. On the evening of April 2, a dynamic mix of partners, customers and visitors came together for a night of refreshing drinks, great conversations and meaningful connections. Hosted by Cybus, the gathering created the perfect setting for exchanging impressions from the trade show and tackling key topics in industrial transformation. One thing was clear: subjects like energy management, edge-to-cloud architectures and industrial ecosystems are gaining critical importance for both solution providers and factory operators.

A big thank you to everyone who joined us – your energy, insights and enthusiasm made the event truly special.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information