-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

News | 21.07.2025

Cutting-edge technologies, intelligent machines, connected processes – the dynamic ecosystem of the Smart Factory promises flexible, self-optimizing production. Fueled by data from countless machines, sensors and IT systems, manufacturers are expected to meet customer needs in real time and set new standards for quality.

That’s the theory.

The reality, however, often looks very different.

In many industrial environments shaped by legacy IT and OT systems, manual processes still dominate daily operations.

Before data can become a driving force for innovation, companies face a series of stubborn challenges:

The solution: A data space that connects everything

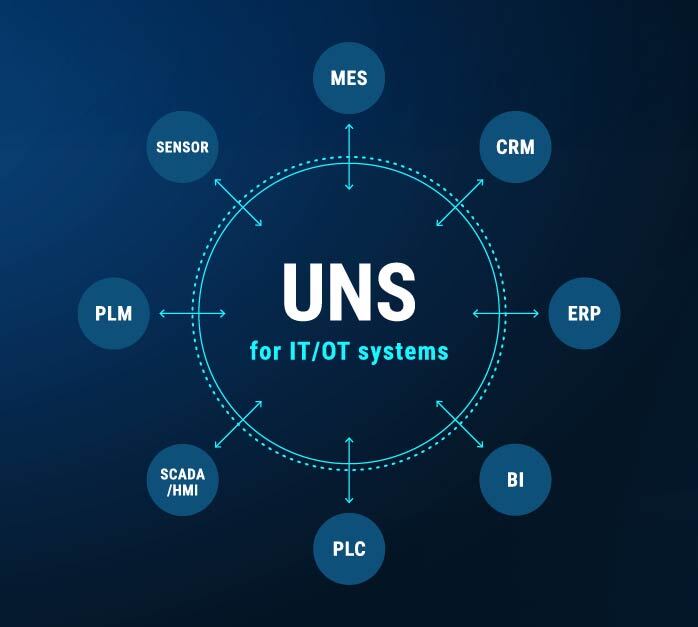

The Unified Namespace (UNS) changes the game of industrial data integration – shifting from static storage to dynamic, real-time data availability in one unified organizational structure.

The Unified Namespace is a central data structure for modern industrial data integration.

It brings together all relevant data sources – from machines to IT systems – in a single, semantically structured digital data space.

This structured layer serves as a single source of truth for real-time data, providing IT and OT systems alike with consistent and up-to-date information.

Unlike traditional architectures where data is trapped in vertical ISA-95 layers, the UNS follows a horizontal approach: data is made centrally available with full context, often using an MQTT broker in a publish-subscribe model.

The result is an open, scalable, vendor-neutral data space that spans the entire enterprise – from the shop floor to the ERP system.

Unlike Data Lakes or Historian systems, the Unified Namespace focuses not on storing data volumes but on contextualizing and structuring live data across all areas of the organization. It establishes a continuous, real-time data environment that enables flexible, secure information exchange. This creates the foundation for a modern, connected industrial architecture where data is no longer isolated but made usable across the entire enterprise. Even existing systems like Data Lakes and Historians can be connected to the UNS and benefit from unified structures and immediate availability.

For manufacturers, the Unified Namespace is more than an integration layer – it’s a strategic capability, both technically and organizationally.

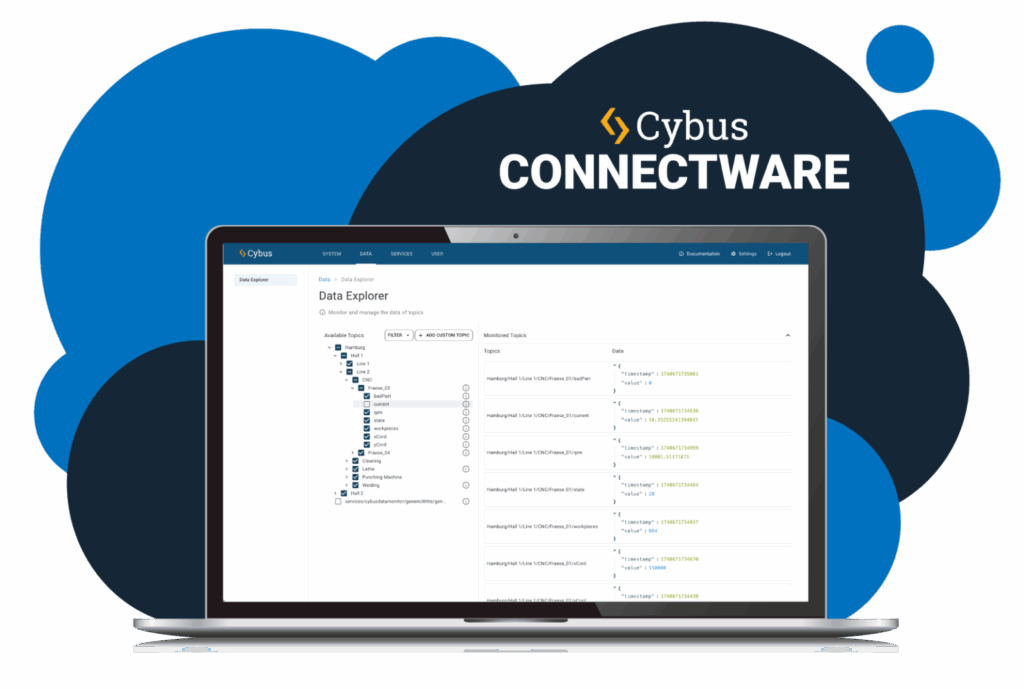

To implement a Unified Namespace successfully, you need a foundation that is scalable, secure and future-ready like Cybus Connectware. Cybus Connectware enables full data infrastructure management based on the Infrastructure as Code principle. This makes automation, version control and fast rollouts a reality – a major advantage over manual or proprietary integration approaches.

Through standardized definitions of data flows, access rights and structures, a reusable, versioned data space is created for the entire production network.

As a technology-neutral Industrial Data Management solution, Cybus Connectware unifies IT and OT on one consistent data layer, turning growth into a predictable, manageable process.

The Unified Namespace is far more than a technical concept – it’s the foundation of a connected, agile and scalable production environment. It breaks down data silos, establishes a shared semantic layer and connects systems, applications and processes across the enterprise.

Cybus Connectware provides the ideal technological foundation for building and operating a Unified Namespace going far beyond the capabilities of a standard MQTT broker or specialized integration platform.

It combines technological flexibility, central management, security, scalability and cost transparency in a future-proof solution creating the basis for the digital production of tomorrow. Both centralized and distributed UNS architectures can be implemented efficiently: with local instances per site that operate independently and synchronize selectively with a central cloud instance when needed.

The result is a globally orchestrated data environment that unites local autonomy, global transparency, and enterprise-wide governance – powered by Cybus Connectware as the Industrial Data Management solution.

Discover how other manufacturers have successfully implemented their Unified Namespace.

Contact us for a personalized consultation and let’s make your production ready for the digital future.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Turnstile. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information