-

-

Insights & knowledge

For users

Support

-

Ecosystem

About Cybus

CONNECTIVITY PORTFOLIO | CONNECT Heidenhain DNC

Heidenhain controllers can be found in many widely used CNC machines. These controllers provide the Heidenhain DNC interface, also referred to as “option 18”, which enables vertical integration of devices and allows users to access data and functions of a system. The DNC protocol is based on Remote Procedure Calls (RPC), which means that it carries out operations by calling methods on the target device. You can find a list of available methods in Cybus Docs.

The Cybus Connectware makes it possible to easily interact with CNC machines via the Heidenhain DNC communication protocol. It offers the opportunity to read all machine data and status information, to manipulate the tool and pocket table, and to access data as well as files on the filesystem and all other methods provided by the Heidenhain DNC Interface.

With Cybus Connectware, you can make Heidenhain Data available on MQTT or OPC UA, optionally using a companion spec like Umati. Data can be easily normalized and forwarded to database systems, MES systems, data lakes or IoT Platforms like Adamos, Azure, AWS or others.

Compatibility has been verified for the following controller types, others can be evaluated on request:

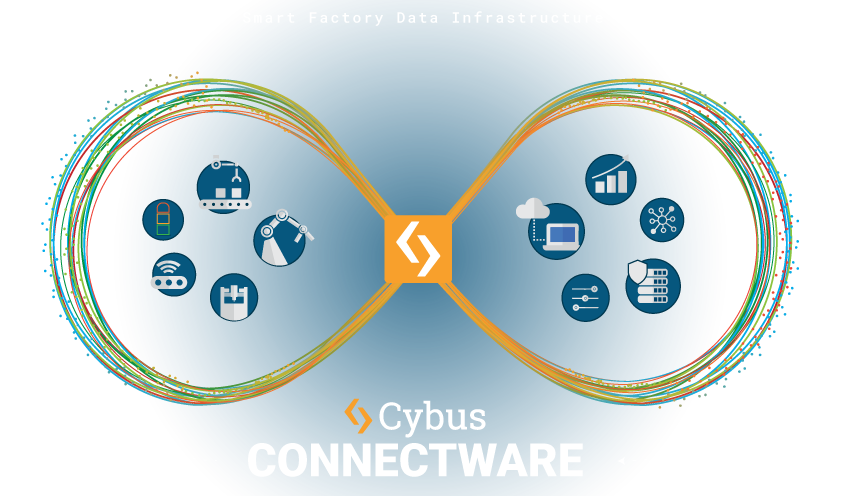

CYBUS CONNECTWARE

The leading Factory Data Hub Connectware is suitable for the first steps of digitization up to the Smart Factory transformation. In addition to universal shopfloor connectivity, Connectware creates a scalable data infrastructure for digital projects without limits. One single platform for all IIoT projects, independent of applications and vendors.

Would you like to discover what you can achieve with Cybus

Connectware in your factory? We are happy to discuss how you will realize your digital projects efficiently and quickly.

Sales manager

You are currently viewing a placeholder content from Zoho Bookings. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information ‘You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information